Photo from wikipedia

Progress in tissue engineering is dependent on the availability of suitable biomaterials. In an effort to overcome the brittleness of poly(3-hydroxybutyrate), P(3HB), a natural biodegradable polyester, and widen its biomedical… Click to show full abstract

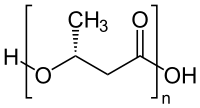

Progress in tissue engineering is dependent on the availability of suitable biomaterials. In an effort to overcome the brittleness of poly(3-hydroxybutyrate), P(3HB), a natural biodegradable polyester, and widen its biomedical applications, plasticising of P(3HB) with oligomeric substances of related structure has been studied. A biosynthesised medium-chain-length polyhydroxyalkanoate (mcl-PHA) copolymer, the plasticiser precursor, was obtained using vegetable waste frying oil as a sole carbon source. The mcl-PHA was transformed into an oligomeric derivative by acid hydrolysis. The plasticising effect of the oligomeric mcl-PHA on P(3HB) was studied via characterisation of thermal and mechanical properties of the blends in the course of ageing at ambient conditions. Addition of oligomeric mcl-PHA to P(3HB) resulted in softer and more flexible materials based entirely on PHAs. It was shown that the oligomeric mcl-PHA transformed highly crystalline P(3HB) into materials with a dominant amorphous phase when the content of oligomeric mcl-PHA exceeded 10 wt%. In vitro biocompatibility studies of the new binary PHA materials showed high viability and proliferation of C2C12 myoblast cells. Thus, the proposed approach for P(3HB) plasticisation has the potential for the generation of more pliable biomaterials based on P(3HB) which can find application in unique soft tissue engineering applications where a balance between stiffness, tensile strength and ductility is required. STATEMENT OF SIGNIFICANCE Polyhydroxyalkanoates, a broad family of natural biodegradable and biocompatible polymers, have emerged as highly promising biomaterials both for bulk and biomedical applications. Here we describe an approach to tune the mechanical properties of stiff and brittle poly(3-hydroxybutyrate) and thereby to expand its potential biomedical applications. Plasticisation, a common practice in the plastic industry to modify polymer mechanical properties, has been used very cautiously for biomedical applications due to plasticiser toxicity and migration. We have developed a plasticiser for poly(3-hydroxybutyrate) based on a structurally related but softer and pliable medium chain length polyhydroxyalkanoate. Additives of oligomeric derivatives of this polymer improved ductility of poly(3-hydroxybutyrate), greatly widening the future applicability of this well-established biomaterial. In parallel, the binary polyhydroxyalkanoate materials also exhibited improved cell attachment and proliferation, a highly desirable outcome.

Journal Title: Acta biomaterialia

Year Published: 2018

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!