Photo from wikipedia

Pump-controlled hydraulic circuits are proven to be more efficient than conventional valve-controlled circuits. Pump-controlled hydraulic circuits for double rod cylinders are well developed and are in use in many practical… Click to show full abstract

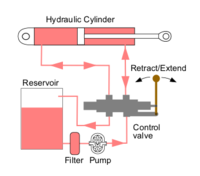

Pump-controlled hydraulic circuits are proven to be more efficient than conventional valve-controlled circuits. Pump-controlled hydraulic circuits for double rod cylinders are well developed and are in use in many practical applications. Existing pump-controlled circuits for single-rod actuators experience oscillation issues under specific operating conditions; that is identified as a critical operating zone on the load-velocity plane. The challenge in these circuits is to find out the proper way to compensate for the differential flow at both sides of the cylinder in all operating conditions. The two main types of valves commonly used by researchers, to compensate for differential flow in single-rod cylinder circuits, are: pilot-operated check valves, and shuttle valves. In this research, a performance comparison between circuits equipped with either valves, in terms of the size of the critical zone and the oscillations’ characteristics, was accomplished. Simulation studies showed that the circuits that utilize pilot-operated check valves possesses smaller oscillatory zones and less severe oscillations, when compared to circuits with shuttle valves. Experimental work verified the simulation results and proved the accuracy of the mathematical models. Hence, pump-controlled circuits with pilot-operated check valves are recommended to be the basic platform for further efforts to solve the oscillation problem in pump-controlled circuits.

Journal Title: Actuators

Year Published: 2023

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!