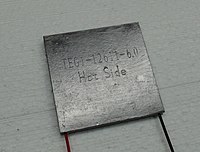

Photo from wikipedia

Herein, a full thermoelectric (TE) device fabricated on textile using atomic layer deposition (ALD) and molecular layer deposition (MLD) thin‐film techniques is demonstrated. The device consists of n‐type ALD‐grown ZnO… Click to show full abstract

Herein, a full thermoelectric (TE) device fabricated on textile using atomic layer deposition (ALD) and molecular layer deposition (MLD) thin‐film techniques is demonstrated. The device consists of n‐type ALD‐grown ZnO or ALD/MLD‐grown ZnO‐organic components and p‐type spray/immersion‐coated PEDOT:PSS components. Different fabrication strategies and device designs (vertical and longitudinal) are investigated. The performance is evaluated by measuring the open‐circuit voltage generated by the device over a range of temperature differences (between the hot and cold sides) up to 60 °C. At a fixed ΔT, the voltage generated is found to increase with increasing ZnO or ZnO‐organic film thickness. An attractive feature with both ALD and MLD is that the film grows in a conformal manner on the textile fibers so that the entire textile piece becomes an active part of the device, corresponding to a remarkable coating‐thickness increase. The voltage generated can also be increased by combining more TE pairs (even by just increasing the number of pairs by cutting the TE pads into smaller pieces). This research has thus proven the feasibility of ALD and MLD techniques in combination with a textile substrate in reinforcing the prospects of wearable thermoelectrics.

Journal Title: Advanced Engineering Materials

Year Published: 2020

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!