Photo from wikipedia

A key challenge in the development of materials for applications in the fields of opto‐ and nanoelectronics, catalysis, separation, and energy conversion is the ability to fabricate 3D inorganic semiconductive… Click to show full abstract

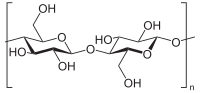

A key challenge in the development of materials for applications in the fields of opto‐ and nanoelectronics, catalysis, separation, and energy conversion is the ability to fabricate 3D inorganic semiconductive nanostructures in a precisely‐controlled and cost‐effective manner. This work describes the fabrication of 3D nanostructured TiO2 monoliths by coating ultraporous cross‐linked cellulose nanocrystal (CNC) aerogel templates with TiO2 layers of controlled thickness via atomic layer deposition (ALD). Following calcination, the resulting hollow inorganic ultraporous 3D networks form the thinnest self‐supporting semiconductive structure (7 nm) fabricated directly on a conductive substrate. The CNC‐templated ALD–TiO2 electrodes are applied toward photoelectrochemical water splitting. The results show that a TiO2 coating as thin as 15 nm produces a maximum water splitting efficiency, resulting in materials savings and reduced fabrication time.

Journal Title: Advanced Materials Interfaces

Year Published: 2021

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!