Photo from wikipedia

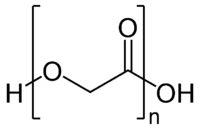

In this study, multifilament fibers based on neat poly(lactic acid) (PLA), PLA/cellulose nanowhiskers (CNWs), and PLA/cellulose microcrystalline (MCC) loaded at 1 and 3 wt.% were prepared by melt-spinning process in… Click to show full abstract

In this study, multifilament fibers based on neat poly(lactic acid) (PLA), PLA/cellulose nanowhiskers (CNWs), and PLA/cellulose microcrystalline (MCC) loaded at 1 and 3 wt.% were prepared by melt-spinning process in the presence of PLA-grafted maleic anhydride (PLA-g-MA) used as the compatibilizer and PEG as the plasticizer. This study showed that the incorporation of MCC in PLA matrix whatever the loading rate was not suitable for multifilament fibers spinning compared with CNW, due to the restricted drawability and a poor dispersion of the MCC within the PLA matrix. Furthermore, the whole characterization studies indicated that the incorporation of 1 wt.% of CNW in PLA with addition of the compatibilizer led to better thermal stability, flame retardancy, and multifilament tensile properties compared with neat PLA and with other filled PLA multifilament fibers.

Journal Title: Advances in Polymer Technology

Year Published: 2018

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!