Photo from wikipedia

Extrusion additive manufacturing is widely used to fabricate polymer‐based 3D bone scaffolds. However, the insight views of crystal growths, scaffold features and eventually cell‐scaffold interactions are still unknown. In this… Click to show full abstract

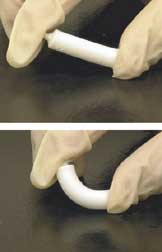

Extrusion additive manufacturing is widely used to fabricate polymer‐based 3D bone scaffolds. However, the insight views of crystal growths, scaffold features and eventually cell‐scaffold interactions are still unknown. In this work, melt and solvent extrusion additive manufacturing techniques are used to produce scaffolds considering highly analogous printing conditions. Results show that the scaffolds produced by these two techniques present distinct physiochemical properties, with melt‐printed scaffolds showing stronger mechanical properties and solvent‐printed scaffolds showing rougher surface, higher degradation rate, and faster stress relaxation. These differences are attributed to the two different crystal growth kinetics, temperature‐induced crystallization (TIC) and strain‐induced crystallization (SIC), forming large/integrated spherulite‐like and a small/fragmented lamella‐like crystal regions respectively. The stiffer substrate of melt‐printed scaffolds contributes to higher ratio of nuclear Yes‐associated protein (YAP) allocation, favoring cell proliferation and differentiation. Faster relaxation and degradation of solvent‐printed scaffolds result in dynamic surface, contributing to an early‐stage faster osteogenesis differentiation.

Journal Title: Advanced Science

Year Published: 2022

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!