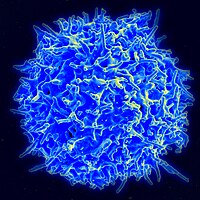

Photo from wikipedia

Adoptive T‐cell therapy (ACT) has emerged as a promising new way to treat systemic cancers such as acute lymphoblastic leukemia. However, the robustness and reproducibility of the manufacturing process remains… Click to show full abstract

Adoptive T‐cell therapy (ACT) has emerged as a promising new way to treat systemic cancers such as acute lymphoblastic leukemia. However, the robustness and reproducibility of the manufacturing process remains a challenge. Here, a single‐use 24‐well microbioreactor (micro‐Matrix) was assessed for its use as a high‐throughput screening tool to investigate the effect and the interaction of different shaking speeds, dissolved oxygen (DO), and pH levels on the growth and differentiation of primary T cells in a perfusion‐mimic process. The full factorial design allowed for the generation of predictive models, which were used to find optimal culture conditions. Agitation was shown to play a fundamental role in the proliferation of T cells. A shaking speed of 200 rpm drastically improved the final viable cell concentration (VCC), while the viability was maintained above 90% throughout the cultivation. VCCs reached a maximum of 9.22 × 106 cells/ml. The distribution of CD8+ central memory T cells (TCM), was found to be largely unaffected by the shaking speed. A clear interaction between pH and DO (p < .001) was established for the cell growth and the optimal culture conditions were identified for a combination of 200 rpm, 25% DO, and pH of 7.4. The combination of microbioreactor technology and Design of Experiment methodology provides a powerful tool to rapidly gain an understanding of the design space of the T‐cell manufacturing process.

Journal Title: Biotechnology and Bioengineering

Year Published: 2020

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!