Photo from wikipedia

2,5-Furandicarboxylic acid (FDCA) has become an increasingly desirable platform chemical to replace terephthalic acid in the production of a variety of polymeric materials, including polyethylene terephthalate. FDCA can be produced… Click to show full abstract

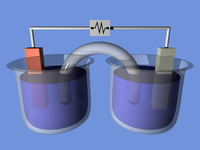

2,5-Furandicarboxylic acid (FDCA) has become an increasingly desirable platform chemical to replace terephthalic acid in the production of a variety of polymeric materials, including polyethylene terephthalate. FDCA can be produced by the oxidation of 5-hydroxymethylfurfural (HMF), which can be derived from cellulosic biomass. Oxidation of HMF to FDCA is typically performed under basic conditions. Separation of FDCA is most easily accomplished by lowering the pH until FDCA is insoluble and filtering it from solution. In a large-scale process, this would lead to a high operating cost to purchase the required acid and base and to dispose of the resulting salt waste. In this study, electrochemical oxidation of HMF was carried out in acidic media by using a manganese oxide (MnOx ) anode to remove the need to vary the pH to separate FDCA. The MnOx anode afforded a FDCA yield of 53.8 % in a pH 1 H2 SO4 solution, in which FDCA precipitation occurred spontaneously from the same reaction solution without altering the pH or other aspects of the solution composition. Electrochemical oxidation in acidic media offers a new pathway to convert HMF into maleic acid, which is another desirable biomass-derived platform molecule. The performance of the MnOx anode was investigated in comparison with that of a Pt anode to identify unique electrocatalytic properties of the MnOx anode for HMF oxidation.

Journal Title: ChemSusChem

Year Published: 2018

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!