Photo from wikipedia

The nickel-rich cathode LiNi0.8Co0.1Mn0.1O2 (NCM811) possesses the advantages of high reversible specific capacity and low cost, thus regarded as a promising cathode material for lithium-ion batteries (LIBs). However, the capacity… Click to show full abstract

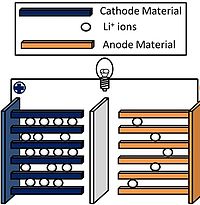

The nickel-rich cathode LiNi0.8Co0.1Mn0.1O2 (NCM811) possesses the advantages of high reversible specific capacity and low cost, thus regarded as a promising cathode material for lithium-ion batteries (LIBs). However, the capacity of the NCM811 decays rapidly at high voltage due to the extremely unstable electrode/electrolyte interphase. The discharge capability at low temperature is also impaired because of the increasing interfacial impedance. Herein, a low-cost film-forming electrolyte additive with multi-function, phenylboronic acid (PBA), is employed to modify the interphasial properties of the NCM811 cathode. Theoretical calculation and experimental results show that PBA constructs a highly conductive and steady cathode electrolyte interphase (CEI) film via preferential oxidation decomposition, which greatly improves the interfacial properties of the NCM811 cathode at room (25 ℃) and low temperature (-10 ℃). Specifically, the capacity retention of NCM811/Li cell is increased from 68% to 87% after 200 cycles with PBA additive. Moreover, the NCM811/Li cell with PBA additive delivers higher discharge capacity under -10 ℃ at 0.5C (173.7 mAh/g vs. 111.1 mAh/g). Based on the improvement of NCM811 interphasial properties by additive PBA, the capacity retention of NCM811/graphite full-cell is enhanced from 49% to 65% after 200 cycles.

Journal Title: ChemSusChem

Year Published: 2022

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!