Photo from wikipedia

Lithium‐ion battery packs have been generally used as the power source for electric vehicles. Heat generated during discharge and limited space in the battery pack may bring safety issues and… Click to show full abstract

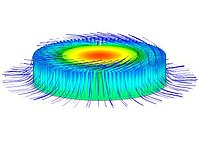

Lithium‐ion battery packs have been generally used as the power source for electric vehicles. Heat generated during discharge and limited space in the battery pack may bring safety issues and negative effect on the battery pack. Battery thermal management system is indispensable since it can effectively moderate the temperature rise by using a simple system, thereby improving the safety of battery packs. However, the comprehensive investigation on the optimal design of battery thermal management system with liquid cooling is still rare. This article develops a comprehensive methodology to design an efficient mini‐channel cooling system, which comprises thermodynamics, fluid dynamics, and structural analysis. The developed methodology mainly contains four steps: the design of the mini‐channel cooling system and computational fluid dynamics analysis, the design of experiments and selection of surrogate models, formulation of optimization model, and multi‐objective optimization for selection of the optimum scheme for mini‐channel cooling battery thermal management system. The findings in the study display that the temperature difference decreases from 8.0878 to 7.6267 K by 5.70%, the standard temperature deviation decreases from 2.1346 to 2.1172 K by 0.82%, and the pressure drop decreases from 302.14 to 167.60 Pa by 44.53%. The developed methodology could be extended for industrial battery pack design process to enhance cooling effect thermal performance and decrease power consumption.

Journal Title: International Journal of Energy Research

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!