Photo from wikipedia

In this study, the morphological, physical, and mechanical properties of maple fiber self-hybrid composites reinforced linear low-density polyethylene (LLDPE) have been investigated for different concentration (10, 20, and 30%) and… Click to show full abstract

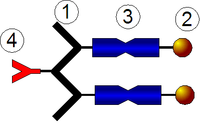

In this study, the morphological, physical, and mechanical properties of maple fiber self-hybrid composites reinforced linear low-density polyethylene (LLDPE) have been investigated for different concentration (10, 20, and 30%) and ratio (100/0, 75/25, 50/50, 25/75, and 0/100) of short (125–250 μm), medium (250–355 μm), and long (355–500 μm) fibers. Maple surface treatment with a coupling agent (maleated polyethylene, MAPE) was also investigated. The results show that surface treatment increased the tensile modulus and strength, and impact strength. Finally, the self-hybrid composites gave better properties than single size fibers since a positive deviation from the linear law of mixture was observed, especially at 20% wt. For example, a 75/25 ratio of medium/short or long/short fibers produced a tensile modulus and tensile strength between 13% and 33% higher than composites formulated with a single fiber size. POLYM. COMPOS., 2017. © 2017 Society of Plastics Engineers

Journal Title: Polymer Composites

Year Published: 2018

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!