Photo from wikipedia

Particulate matter (PM) is one of the most severe air pollutants and poses a threat to human health. Air filters with high filtration efficiency applied to the source of PM… Click to show full abstract

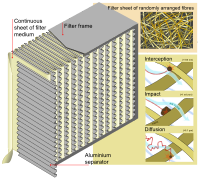

Particulate matter (PM) is one of the most severe air pollutants and poses a threat to human health. Air filters with high filtration efficiency applied to the source of PM are an effective way to reduce pollution. However, many of the present filtration materials usually fail because of their high pressure drop under high-velocity airflow and poor thermal stability at high temperatures. Herein, a highly porous Si3 N4 nanofiber sponge (Si3 N4 NFS) assembled by aligned and well-interconnected Si3 N4 nanofibers is designed and fabricated via chemical vapor deposition (CVD). The resulting ultralight Si3 N4 NFS (2.69 mg cm-3 ) processes temperature-invariant reversible strechability (10% strain) and compressibility (50% strain), which enables its mechanical robustness under high-velocity airflow. The highly porous and aligned microstructure result in a Si3 N4 NFS with high filtration efficiency for PM2.5 (99.97%) and simultaneous low pressure drop (340 Pa, only <0.33% of atmospheric pressure) even under a high gas flow velocity (8.72 m s-1 ) at a high temperature (1000 °C). Furthermore, the Si3 N4 NFS air filter exhibits good long-term service ability and recyclability. Such Si3 N4 NFS with aligned microstructures for highly efficient gas filters provides new perspectives for the design and preparation of high-performance filtration materials.

Journal Title: Small

Year Published: 2021

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!