Photo from wikipedia

Thanks to their unique advantages, additive manufacturing technologies are revolutionizing almost all sectors of the industrial and academic worlds, including tissue engineering and regenerative medicine. In particular, 3D bioprinting is… Click to show full abstract

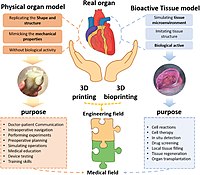

Thanks to their unique advantages, additive manufacturing technologies are revolutionizing almost all sectors of the industrial and academic worlds, including tissue engineering and regenerative medicine. In particular, 3D bioprinting is rapidly emerging as a first-choice approach for the fabrication-in one step-of advanced cell-laden hydrogel constructs to be used for in vitro and in vivo studies. This technique consists in the precise deposition layer-by-layer of sub-millimetric hydrogel strands in which living cells are embedded. A key factor of this process consists in the proper formulation of the hydrogel precursor solution, the so-called bioink. Ideal bioinks should be able, on the one side, to support cell growth and differentiation and, on the other, to allow the high-resolution deposition of cell-laden hydrogel strands. The latter feature requires the extruded solution to instantaneously undergo a sol-gel transition to avoid its collapse after deposition.To address this challenge, researchers are recently focusing their attention on the synthesis of several derivatives of natural biopolymers to enhance their printability. Here, we present an approach for the synthesis of photocurable derivatives of natural biopolymers-namely, gelatin methacrylate, hyaluronic acid methacrylate, chondroitin sulfate methacrylate, and PEGylated fibrinogen-that can be used to formulate tailored innovative bioinks for coaxial-based 3D bioprinting applications.

Journal Title: Methods in molecular biology

Year Published: 2021

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!