Photo from wikipedia

In the context of lightweight design and modern hybrid technologies, the importance of structural and soft adhesives in industrial applications is increasing. Therefore, this paper examines a relatively soft polyurethane… Click to show full abstract

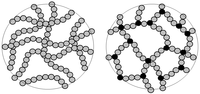

In the context of lightweight design and modern hybrid technologies, the importance of structural and soft adhesives in industrial applications is increasing. Therefore, this paper examines a relatively soft polyurethane adhesive characterized by showing nonlinear viscoelastic behavior at room temperature and enduring large deformations. It is well suited for applications under dynamic loadings and can compensate gap changes generated by materials with different thermal expansion coefficients. Theoretically, the examined one-component polyurethane adhesive can be cured either thermally or through humidity, resulting in the same mechanical characteristics. Comparing both curing reactions, humidity curing is much slower than thermal curing. The latter can be controlled through the temperature, which may be applied through heating rates of up to $$150\,\hbox {K}\,\hbox {min}^{-1}$$ 150 K min - 1 . However, in comparison with metals polyurethane conducts the heat with a much smaller rate which results in high temperature gradients within the adhesive layer. This paper focuses on the modeling of a fast-curing polyurethane adhesive under consideration of the changes in density and thermomechanical material properties induced by thermal curing. Therefore, the material properties need to be observed throughout the thermal curing process, from the uncured fluid to the cured rubber material. In the long term, the accurate prediction of the materials behavior will ultimately facilitate the optimization of the curing process.

Journal Title: Continuum Mechanics and Thermodynamics

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!