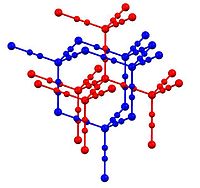

Photo from wikipedia

Abstract Polydimethylsiloxane (PDMS) is a commonly used material in biomedical engineering (Sollier et al. in Lab Chip 11(22):3752–3765, 2011; Palchesko et al. in PLoS ONE 7(12):e51499, 2012; Berthier et al.… Click to show full abstract

Abstract Polydimethylsiloxane (PDMS) is a commonly used material in biomedical engineering (Sollier et al. in Lab Chip 11(22):3752–3765, 2011; Palchesko et al. in PLoS ONE 7(12):e51499, 2012; Berthier et al. in Lab Chip 12(7):1224–1237, 2012). Its elastic nature makes PDMS especially attractive for microfluidic large-scale integration (mLSI) technology where micromechanical valves are actuated by deflecting a PDMS membrane under pressure. Therefore, understanding and control of PDMS elastic properties have commercial and scientific significance. In this study, we have investigated the effects of pre-polymer/cross-linker storage conditions on the mechanical properties of cured PDMS films as well as on microfluidic devices. We have showed that when the uncured components of PDMS are exposed to different humidity conditions, the elasticity of the PDMS changes and this is revealed as a change in the Young’s modulus of the cured PDMS. The high humidity (~85%) exposure for 24 h causes PDMS to become softer as confirmed by a significant decrease in the Young’s modulus values from 1.2 to 0.9 MPa. Furthermore, as the PDMS is exposed to high humidity conditions for longer periods (72 h), the Young’s modulus decreases down to 0.7 MPa. We found that exposing only the pre-polymer PDMS (Part A) to humid air does not alter the cured PDMS properties significantly, whereas exposure of the cross-linker (Part B) is responsible for the elasticity change. We have strictly controlled the storage humidity to build more reliable microfluidic chips using mLSI. As a result, actuation pressure of valves (10 psi) and defects of devices (in <30% of chips) are significantly reduced. These results suggest that to improve the manufacturing yield and reliability of PDMS devices, storage humidity should be controlled immediately after the material synthesis.

Journal Title: Microfluidics and Nanofluidics

Year Published: 2017

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!