Photo from wikipedia

Cellulose nanofibers (CNF) have increasing relevance in different applications, for instance, in the paper industry as a sustainable strength additive. This application is especially beneficial for recycled paper, which reaches… Click to show full abstract

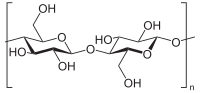

Cellulose nanofibers (CNF) have increasing relevance in different applications, for instance, in the paper industry as a sustainable strength additive. This application is especially beneficial for recycled paper, which reaches higher product quality despite its limitations. CNF change paper properties and also can affect the production process, especially the drainage stage, in which retention additives (RA) are commonly used to promote interaction of cellulose fibers. CNF probably interact with fibers and RA, affecting the drainage stage. However, these interactions vary depending on the type and flocculation mechanism of RA. This research is aimed at establishing possible synergies between CNF and RA to improve paper strength, avoiding negative effects on the drainage process. No further RA were used to retain CNF, taking advantage of the RA already used in the process. Polyvinylamine, chitosan, cationic starch, C-PAM, and C-PAM-B were selected as RA. CNF from eucalyptus kraft pulp and corn stalk organosolv pulp were tested. Strength properties of laboratory sheets were studied, and interactions were assessed by measuring Z-potential. Synergies between PVA, chitosan, C-PAM, and C-PAM-B with CNF were found. Drainage time decreased ranging between 30 and more than 40% using CNF. Strength depended on RA and formation quality. Among the studied options, CNF with C-PAM-B or chitosan resulted in the best formation and higher strengths with a significant drainage time reduction.

Journal Title: Cellulose

Year Published: 2017

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!