Photo from wikipedia

Herein, lignocellulosic nanofibrils (LCNF) suspension containing 0.1, 3.9, and 17.2 wt% lignin were utilized to fabricate films by filtration and pressing process. The stiff nature of fibrils containing lignin made… Click to show full abstract

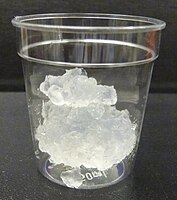

Herein, lignocellulosic nanofibrils (LCNF) suspension containing 0.1, 3.9, and 17.2 wt% lignin were utilized to fabricate films by filtration and pressing process. The stiff nature of fibrils containing lignin made them less able to conform during filtration, resulting in more uneven surface structure with higher roughness value. Lignin in the films interfered in hydrogen bonding between cellulose nanofibrils, thus impairing mechanical property of the film, such as tensile stress and Young’s modulus. Due to the presence of chromophore groups, lignin absorbed light and the light transmittance of film was decreased. However, the film containing lignin displayed unusually high hydrophobicity with water contact angle of 88° and maximal weight loss temperature (Tmax) of 372 °C. Overall, this study provides useful knowledge for understanding the result of lignin on the formation, surface morphology and physical behavior of LCNF films, especially in related bioproducts that requires low hydrophilicity, high roughness and high thermal stability.

Journal Title: Cellulose

Year Published: 2018

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!