Photo from wikipedia

In this paper three newly synthesized imidazolium ionic liquids with different structures of cations were used for hydrolysis of cellulose. It was found that type of the cation has a… Click to show full abstract

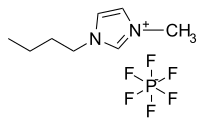

In this paper three newly synthesized imidazolium ionic liquids with different structures of cations were used for hydrolysis of cellulose. It was found that type of the cation has a great influence on particle size and dispersity of produced cellulosic materials. The use of an ionic liquid with a cation with an aliphatic substituent resulted in filler characterized with wide dispersity range and some particles larger than 2 µm. Introduction of methyl group into imidazolium ring was responsible for production of particles below 350 nm. Such particles were obtained also during hydrolysis of cellulose with ionic liquid containing a benzyl substituent with that difference that in this case particles had definitely narrower dispersity range. Moreover, type of the ionic liquid used affected crystallinity degree of the produced celluloses. Produced cellulosic materials were used as fillers for chitosan matrix. A relationship between mechanical properties of polymer composites and the particle size as well as dispersity of cellulose, controlled by chemical modifications of cellulose with innovative ionic liquids was evaluated. Incorporation of filler with established dispersive properties made it possible to form composites characterized by the assumed properties, for example with high values of Young’s modulus, tensile strength or elongation at break. Understanding the dependence between the structure of ionic liquids and dispersive properties of cellulose is an important step toward the design of composite materials with optimal mechanical properties.Graphical abstract

Journal Title: Cellulose

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!