Photo from wikipedia

Hemicellulose separation/removal from cellulosic fibers is critical for manufacturing high-purity cellulose (dissolving pulp). In this communication, a combined system of using both urea and NaOH was studied to enhance the… Click to show full abstract

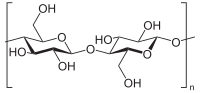

Hemicellulose separation/removal from cellulosic fibers is critical for manufacturing high-purity cellulose (dissolving pulp). In this communication, a combined system of using both urea and NaOH was studied to enhance the separation/removal of hemicellulose from a softwood sulfite dissolving pulp. The urea/NaOH treatment significantly improves the hemicellulose removal. With a 1% urea concentration and 5% NaOH concentration, the hemicellulose content of resultant pulp decreased from 11.22 to 3.99%, which was compared to 6.56% of the control NaOH treatment (without the addition of urea under otherwise the same conditions). Consequently, the alpha-cellulose content of the urea/NaOH-treated pulp was higher than that from the control NaOH treatment (96.02% and 93.94%, respectively). Additionally, the urea/NaOH process was more selective in terms of removing hemicellulose. The underlying mechanism to account for the improved performance of the urea/NaOH process will be discussed.

Journal Title: Cellulose

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!