Photo from wikipedia

The processing quality of the grooves of a nuclear-fuel rod will directly affect the quality of the finished nuclear-fuel rod. Due to the highly reflective, microscopic, and annular characteristics of… Click to show full abstract

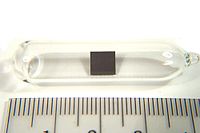

The processing quality of the grooves of a nuclear-fuel rod will directly affect the quality of the finished nuclear-fuel rod. Due to the highly reflective, microscopic, and annular characteristics of nuclear-fuel rod grooves, it has been quite challenging to realize imaging and microscopic defect detection for these grooves. In this work, a machine vision-based defect detection system was developed for nuclear-fuel rod grooves. Through the performance improvement and application of the self-reference template defect detection method, efficient online inspection of nuclear-fuel rod grooves was realized. In the developed system, a combined-light-source imaging system was first designed by combining a coaxial light and a ring light, which realized the clear imaging of a groove. After that, an image expansion strategy was employed to expand the annular groove into a strip-shaped region of interest (ROI). Then, according to the turning processing characteristic of the nuclear-fuel rod groove, the large-size defect detection effect of the self-reference template method was improved by eliminating the anomalous columns prior to generating the self-reference template. The experimental results indicated that the average inspection efficiency of the developed system was 8.026 s/rod, the average false detection rate was 0.183%. The accuracy of the self-reference template method was 87.6%, higher than that of YOLOv2 and Faster R-CNN. The developed system exhibits high inspection efficiency and accuracy, so it can meet the actual detection functions and requirements of production lines, and now it has been successfully applied to actual production.

Journal Title: Journal of Intelligent Manufacturing

Year Published: 2021

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!