Photo from wikipedia

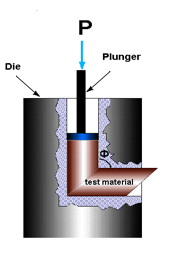

Dynamic equal channel angular pressing experiments are conducted on an aluminum alloy with impact directions (ID) parallel to the rolling direction (RD), transverse direction (TD) and normal direction (ND), referred… Click to show full abstract

Dynamic equal channel angular pressing experiments are conducted on an aluminum alloy with impact directions (ID) parallel to the rolling direction (RD), transverse direction (TD) and normal direction (ND), referred to as the ID$$\parallel $$‖RD, ID$$\parallel $$‖TD and ID$$\parallel $$‖ND loading, respectively. Anisotropic deformation twinning is observed as a result of texture and grain elongation along RD, and the deformation twins can be activated both at grain boundaries and within grain interiors. Large-sized deformation twins (tens of $$\mu $$μm long) form in the ID$$\parallel $$‖RD sample, while few twins are observed in the ID$$\parallel $$‖TD and ID$$\parallel $$‖ND samples during rapid severe plastic deformation. Molecular dynamics simulations are conducted to explain the effects of crystallographic orientations and grain geometry on deformation twinning. The resolved shear stress analysis shows that deformation twinning is easier to occur when the impact direction is along [001] and [110] than [111], and a larger grain dimension along the impact direction leads to a bigger twin size.

Journal Title: Journal of Materials Science

Year Published: 2018

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!