Photo from wikipedia

The relationship between microstructure evolution and mechanical performance of Al–Zn–Mg–Cu alloys with varying Cu/Mg ratios was discussed in detail under different two-step aging (T7X). The results showed that the undissolved… Click to show full abstract

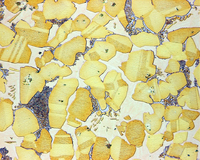

The relationship between microstructure evolution and mechanical performance of Al–Zn–Mg–Cu alloys with varying Cu/Mg ratios was discussed in detail under different two-step aging (T7X). The results showed that the undissolved second-phase particles including σ -Al 7 Cu 2 Fe and T-Al 2 Mg 3 Zn occurred in the quenched Al–Zn–Mg–Cu alloys. When the Cu/Mg ratio approaches 1.64, the S-Al 2 CuMg phase was also observed. Although the Cu/Mg ratio did not change the precipitation sequence of the Al–Zn–Mg–Cu alloys, it changed the coarsening rate and precipitate size distribution during aging process. The Al–Zn–Mg–Cu alloy with the lowest Cu/Mg ratio has the slowest coarsening rate and the highest strength (655 MPa). The fracture morphology of Al–Zn–Mg–Cu alloys changes from the typical brittle fracture to the intergranular-dominated mixed fracture mode or ductile fracture when the Cu/Mg ratios increases. Besides, the T79-aged alloys with varying Cu/Mg ratios have similar grain boundary precipitates (GBPs) and precipitate-free zones (PFZs). The T74-aged alloys with higher Cu/Mg ratio have more coarser GBPs and wider PFZs.

Journal Title: Journal of Materials Science

Year Published: 2020

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!