Photo from wikipedia

The current study explored the application of the electrospinning technique to produce multi-hierarchical composites for hydrogen storage applications. Predetermined control of fibre porosity is expected to enable production of well-defined… Click to show full abstract

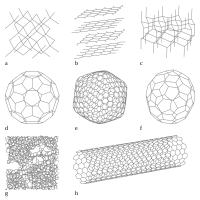

The current study explored the application of the electrospinning technique to produce multi-hierarchical composites for hydrogen storage applications. Predetermined control of fibre porosity is expected to enable production of well-defined hierarchical pore structure. The study involved encapsulation of highly porous zeolite-templated carbon (ZTC) into electrospun fibres and testing of the resulting composites for hydrogen storage. The hydrogen storage capacity of the composite fibres was 1.83%, compared with 2.39 wt% for powder ZTC material. The potential of the electrospinning technique as a shaping option for preparing composites from loose powder is demonstrated. The ZTC–polyacrylonitrile (ZTC-PAN) composite retained about 76% of the hydrogen storage capacity of the ZTC. Vacuum degassing of the ZTC–PAN electrospun composite was also found to enhance the development of porosity, aiding hydrogen penetration into zeolite pores.

Journal Title: Research on Chemical Intermediates

Year Published: 2017

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!