Photo from wikipedia

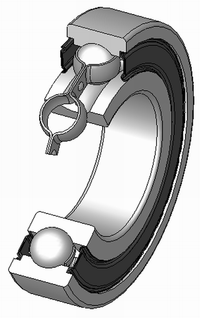

Rolling contact fatigue is the main failure mechanism of tapered roller bearings. This study investigated the fatigue mechanism of rollers in a tapered roller bearing that failed in a run-to-failure… Click to show full abstract

Rolling contact fatigue is the main failure mechanism of tapered roller bearings. This study investigated the fatigue mechanism of rollers in a tapered roller bearing that failed in a run-to-failure test. Roller microstructure and crack morphology were investigated through scanning electron microscopy. A microhardness test was performed to investigate the strain hardening of the roller material induced by rolling contact fatigue. Results showed that microcavities and holes are important influential factors of crack initiation and propagation. Crack propagation angle affects crack morphology and propagation mode. Material strain hardening accelerates crack growth. Furthermore, roller misalignment causes uneven hardenability and severe damage to roller ends.

Journal Title: Science China Technological Sciences

Year Published: 2018

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!