Photo from wikipedia

The ionic liquid polymer electrolyte (IL-PE) membrane is prepared by ultraviolet (UV) cross-linking technology with polyurethane acrylate (PUA), methyl methacrylate (MMA), ionic liquid (Py13TFSI), lithium salt (LiTFSI), ethylene glycol dimethacrylate… Click to show full abstract

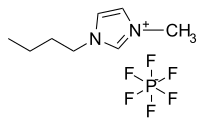

The ionic liquid polymer electrolyte (IL-PE) membrane is prepared by ultraviolet (UV) cross-linking technology with polyurethane acrylate (PUA), methyl methacrylate (MMA), ionic liquid (Py13TFSI), lithium salt (LiTFSI), ethylene glycol dimethacrylate (EGDMA), and benzoyl peroxide (BPO). N-methyl-N-propyl pyrrolidinium bis(trifluoromethanesulfonyl)imide (Py13TFSI) ionic liquid is synthesized by mixing N-methyl-N-propyl pyrrolidinium bromide (Py13Br) and lithium bis(trifluoromethanesulfonyl)imide (LiTFSI). The addition of Py13TFSI to polymer electrolyte membranes leads to network structures by the chain cross-linking. The resultant electrolyte membranes display the room temperature ionic conductivity of 1.37 × 10−3 S cm−1 and the lithium ions transference number of 0.22. The electrochemical stability window of IL-PE is about 4.8 V (vs. Li+/Li), indicating sufficient electrochemical stability. The interfacial resistances between the IL-PE and the electrodes have the less change after 10 cycles than before 10 cycles. IL-PE has better compatibility with the LiFePO4 electrode and the Li electrode after 10 cycles. The first discharge performance of Li/IL-PE/LiFePO4 half-cell shows a capacity of 151.9 mAh g−1 and coulombic efficiency of 87.9%. The discharge capacity is 131.9 mAh g−1 with 95.5% coulombic efficiency after 80 cycles. Therefore, the battery using the IL-PE exhibits a good cycle and rate performance.

Journal Title: Ionics

Year Published: 2017

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!