Photo from wikipedia

The microstructure and mechanical properties of high-strength low-alloy steel were investigated at deformation temperatures of 800-1100 °C and strain rates of 0.1-10 s−1 using an MMS-200 thermal mechanical simulator. The results… Click to show full abstract

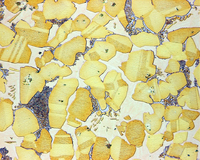

The microstructure and mechanical properties of high-strength low-alloy steel were investigated at deformation temperatures of 800-1100 °C and strain rates of 0.1-10 s−1 using an MMS-200 thermal mechanical simulator. The results indicated that the increased deformation processes observed between the starting and finishing temperatures during hot compression testing caused a polygonal ferrite transformation in the material. The polygonal ferrite grain sizes increased with increasing transformation temperatures and gradually grew larger at higher deformation temperatures. Widmanstätten ferrite and acicular ferrite were also formed at high temperatures from 1000-1100 °C, which accordingly led to an increase in Vickers microhardness. In addition, the flow stress in the material increased with an increase in the strain and a decrease in the deformation temperature.

Journal Title: Journal of Materials Engineering and Performance

Year Published: 2018

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!