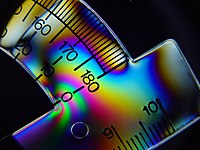

Photo from wikipedia

Shot peening (SP) is a relatively traditional but highly effective mechanical surface treatment that produces a compressive residual stress field in a shot-peened (SPed) surface, which can effectively delay fatigue… Click to show full abstract

Shot peening (SP) is a relatively traditional but highly effective mechanical surface treatment that produces a compressive residual stress field in a shot-peened (SPed) surface, which can effectively delay fatigue crack propagation (FCP) and prolong the service life of engineering materials and structures. A multistep analysis method was developed by combining a numerical simulation of the SP process and the LEFM-based (linear elastic fracture mechanics) superposition principle to study FCP behavior in an SP-induced residual stress field. The SP-induced residual stresses were first simulated by a symmetric cell model and then introduced into a finite element model of the CT specimen. The total stress intensity factors and stress ratios with respect to different crack lengths were calculated according to the LEFM-based superposition principle. The influences of external applied load ratios and SP conditions, including one-sided and double-sided SP, on the FCP behavior of the SPed CT specimen were investigated in detail.

Journal Title: Journal of Materials Engineering and Performance

Year Published: 2020

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!