Photo from wikipedia

The generator technology of electrical discharge machining (EDM) has evolved significantly over the last decades. This enabled EDM to become a crucial technology in die and mold manufacturing. Moreover, EDM… Click to show full abstract

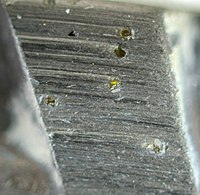

The generator technology of electrical discharge machining (EDM) has evolved significantly over the last decades. This enabled EDM to become a crucial technology in die and mold manufacturing. Moreover, EDM became a more important technology due to the enhanced power efficiency, process-based power dissipation and control strategies especially for tools made from hard materials like cemented carbides. Even though, EDM is considered a standard process for this application today, cemented carbide tools still suffer from premature failure. This is often due to thermally affected rim zones resulting from the EDM processes. Thus, the formation of cracks and white layer should be investigated for contemporary EDM technology. To get a better understanding of the impact of the machining process different cemented carbide grades need to be compared. Therefore in this paper, four kinds of cemented carbides, three versions with normal binder phase content and a variant almost binder free, are analyzed. The materials are machined using roughing and finishing technologies. Then the materials are investigated under the specific consideration of the machined surface integrity of sinking EDM.

Journal Title: Production Engineering

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!