Photo from wikipedia

The recovery of scandium from bauxite residue was studied by selective sulfation roasting and water leaching. The sulfation roasting process of bauxite residue with concentrated sulfuric acid was investigated by… Click to show full abstract

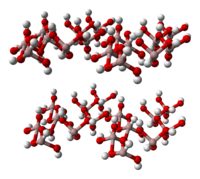

The recovery of scandium from bauxite residue was studied by selective sulfation roasting and water leaching. The sulfation roasting process of bauxite residue with concentrated sulfuric acid was investigated by XRD, SEM and TG-DSC techniques. The results showed that metal oxides in bauxite residue were firstly transformed into their respective sulfates during the sulfation roasting process, while Si was in the form of macromolecular silicic acid. The sulfates of the titanium, iron (III) and aluminum started to decompose to their respective oxides when the roasting temperature was 544°C, 683°C and 716.6°C, respectively. The scandium sulfate was stable when the roasting temperature was below 850°C. About 90% of the scandium can be recovered under the optimum conditions: roasting temperature of 850°C, roasting time of 60 min, concentrated sulfuric acid to bauxite residue rate of 1 ml/g, leaching temperature of 60°C, leaching time of 40 min and liquid to initial bauxite residue ratio of 8:1 ml/g.

Journal Title: JOM

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!