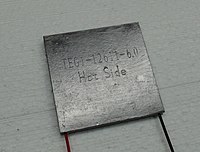

Photo from wikipedia

Thermo-mechanical characterization of a Ni45.3Ti39.7Hf10Pd5 polycrystalline shape memory alloy after aging at 550°C for 3 h was conducted. Thermal cycling under constant stress, superelasticity and loading till failure tests were employed… Click to show full abstract

Thermo-mechanical characterization of a Ni45.3Ti39.7Hf10Pd5 polycrystalline shape memory alloy after aging at 550°C for 3 h was conducted. Thermal cycling under constant stress, superelasticity and loading till failure tests were employed to reveal the shape memory and material properties. Recoverable shape memory strain of 3.8% was achieved under compressive stress of 500 MPa. The sample showed almost perfect superelasticity above 70°C with total recoverable strain of about 4%, but failed at 2340 MPa with compressive strain > 13% at 35°C, and aging was not found to significantly affect its shape memory behavior because of the low volume fraction of precipitates.

Journal Title: JOM

Year Published: 2020

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!