Photo from wikipedia

Long-acting solid lipid microparticles of tetracycline hydrochloride (TH) were prepared using solvent-free twin screw hot melt dispersion technique utilizing biocompatible lipids. Design of experiments was employed to assess the formulation… Click to show full abstract

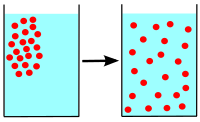

Long-acting solid lipid microparticles of tetracycline hydrochloride (TH) were prepared using solvent-free twin screw hot melt dispersion technique utilizing biocompatible lipids. Design of experiments was employed to assess the formulation and process parameters followed by statistical analysis. Plackett–Burman design generated 12 experiments containing varying ratios of lipids and TH (1:2 to 1:8). Compatibility studies by DSC were conducted on these physical mixtures of drug: lipids to check interactions and obtain an indication of lipids melting range. Microparticles were fabricated and evaluated for flow properties, particle size distribution, surface morphology, drug content, percent entrapment efficiency (PDE), and drug diffusion studies. Impact of critical process parameters on responses like throughput and specific mechanical energy consumption (SMEC) was evaluated using central composite design (CCD). DSC study confirmed compatibility of selected C16 to C18 lipids. Microscopic analysis enabled understanding changes in surface morphology pre- and post-diffusion. Lipid compositions and ratios had shown impact on drug diffusion at 2 h and 72 h. PDE was directly linked to TH: lipid ratio in the formulations. Stability of the microparticles was confirmed by assay and XRD and FTIR analysis on selected formulations. Stearic acid and hydrogenated castor oil revealed significant impact on drug diffusion and micromeritic properties, respectively. Low feed rates and high screw speeds led to increase in SMEC. Morphology of melt agglomerates was controlled by varying the feed rates. Microparticles with anticipated particle size and diffusion profiles were achieved with the outlined process, which were deemed suitable to administer inside periodontal cavities.

Journal Title: Journal of Pharmaceutical Innovation

Year Published: 2021

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!