Photo from wikipedia

The forming limit curve (FLC) of zirconium alloys plays a significant role in the fabrications of spacer grid used for nuclear fuel assembly. The theoretical prediction of FLC has provided… Click to show full abstract

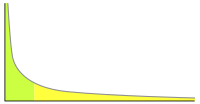

The forming limit curve (FLC) of zirconium alloys plays a significant role in the fabrications of spacer grid used for nuclear fuel assembly. The theoretical prediction of FLC has provided a convenient method to calculate the strain limit during the sheet forming process, but the prediction accuracy of zirconium alloy is still unsatisfactory due to its close-packed-hexagonal (HCP) structure. In this paper, to find a suitable yield surface exponent of zirconium alloys for improving the prediction accuracy, the theoretical FLCs of SZA6 zirconium alloy were calculated by self-programmed numerical codes with different exponent values and the results were compared with the experiments. To explain the mechanism of how the yield surface exponent affects the plastic behavior of SZA6 zirconium alloy, the strain distributions and element strain paths of Nakajima test were analyzed by finite element methods. At last, a suggested value of the yield surface exponent suitable for the FLC prediction of this zirconium alloy is acquired.

Journal Title: International Journal of Material Forming

Year Published: 2021

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!