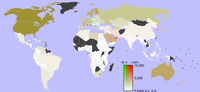

Photo from wikipedia

Dietary fiber (DF) is a promising group of compounds that provides several techno-functionalities to foods. Plant-food materials, as well as fruit and vegetable by-products generated from the agricultural industry, can… Click to show full abstract

Dietary fiber (DF) is a promising group of compounds that provides several techno-functionalities to foods. Plant-food materials, as well as fruit and vegetable by-products generated from the agricultural industry, can be utilized to obtain DF-based techno-functional ingredients. DF compounds are usually extracted and modified with thermal, enzymatic, and chemical treatments. However, these methods require high temperatures, the use of chemical reagents, long extraction times, and usually result in the production of low extraction yields. In this context, ultrasound (US)-assisted extraction (UAE) has proved to increase the extraction yield of different polysaccharides, as well as showing a significant reduction in the processing times and energy consumption. US power, frequency, temperature, residence time, and the sample-solvent interaction (SL; solid–liquid ratio) are the variables that must be considered for the success of UAE applications. Additionally, US can modify polysaccharide structures, producing changes in techno-functional properties such as water holding capacity, swelling capacity, oil holding capacity, and rheological properties, among other characteristics. These properties can improve DF applications and result in new attributes of interest for the food industry. This work aims to present advances and recent studies comparing UAE and conventional extraction methods for specific fiber compounds from fiber-rich by-products not only to evaluate the extraction yield and processing variables but also to compare the composition and techno-functionality of the extracted compounds and their benefits in food applications that can contribute to future utilization of US in the food industry.

Journal Title: Food Engineering Reviews

Year Published: 2020

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!