Photo from wikipedia

The emergency of surface defect would significantly influence the quality of MPCG (Mobile Phone Cover Glass). Therefore, efficient defect detection is highly required in the manufacturing process. Focusing on the… Click to show full abstract

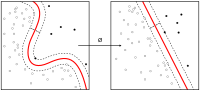

The emergency of surface defect would significantly influence the quality of MPCG (Mobile Phone Cover Glass). Therefore, efficient defect detection is highly required in the manufacturing process. Focusing on the problem, an automatic detection system is developed in this paper. The system adopts backlight imaging technology to improve the signal to noise ration and imaging effect. Then, a modified segmentation method is presented for defect extraction and measurement based on deep neural networks. In the method, a novel data generation process is provided, with which the drawback that huge amount of data is required for training deep structured networks can be overcome. Finally, experiments are well conducted to verify that satisfactory performance is achieved with the proposed method.

Journal Title: International Journal of Precision Engineering and Manufacturing

Year Published: 2018

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!