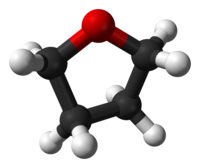

Photo from wikipedia

AbstractBioethanol from lignocellulosic biomass is environment friendly and a renewable source of energy which can serve as alternative to fossil fuels particularly in transport sector. The present study investigates the… Click to show full abstract

AbstractBioethanol from lignocellulosic biomass is environment friendly and a renewable source of energy which can serve as alternative to fossil fuels particularly in transport sector. The present study investigates the efficiency of bioethanol production from pine needles of Pinus roxburghii (PNPR) using thermochemical pretreatment method. The PNPR biomass was subjected to thermochemical pretreatment using dilute concentrations (0.5%, 1%, 1.5%, and 2%) of HCl at a biomass loading of 5%, 10%, and 15%. Maximum reducing sugar (RS) yield of 96 mg/g biomass using one variable at a time (OVAT) approach was achieved using 1% HCl and a biomass loading of 5% (w/v). Central composite design (CCD) tool of response surface methodology (RSM) enhanced the RS yield to 0.2 g/g biomass under the optimized conditions. FTIR analysis revealed reduction in the lignin, cellulose, and hemicellulose content of PNPR biomass during the pretreatment process. Enzymatic hydrolysis was attempted using combinations of cellulase, xylanase, and pectinase commercial enzymes and the highest RS yield obtained was 0.43 g/g biomass. The hydrolysate was then fermented by Saccharomyces cerevisiae (MTCC-36) as well as by a combination of Saccharomyces cerevisiae (MTCC-36) and Pichia stipitis (NCIM-3498) to produce bioethanol. With a conversion efficiency of 90%, maximum bioethanol yield of 0.144 g/g biomass after 24 h was obtained from separate hydrolysis and fermentation (SHF) using combined cultures of S. cerevisiae (MTCC-36) and P. stipitis (NCIM-3498).

Journal Title: Biomass Conversion and Biorefinery

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!