Photo from wikipedia

The microstructure and stress-rupture property of the large-scale complex single crystal (SX) casting DD10 were investigated in high-rate solidification process. It is found that the primary dendrite arm spacing (PDAS)… Click to show full abstract

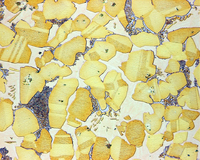

The microstructure and stress-rupture property of the large-scale complex single crystal (SX) casting DD10 were investigated in high-rate solidification process. It is found that the primary dendrite arm spacing (PDAS) does not increase monotonically with the height increase. When across the platform, the temperature gradient increases due to the effect of platform, and the corresponding PDAS decreases. The distribution of eutectic volume fraction in large-scale complex SX casting is affected by PDAS, solid back diffusion, and the development of high order dendrites. The eutectic volume fraction contained in the sample taken below the platform decreases with the height increase. While the eutectic volume fraction contained in the sample taken upper the platform increases gradually with the height increase. After heat treatment, most of the γ/γ′ eutectics are eliminated and the components are distributed uniformly. The similar stress rupture properties of the samples at different heights in the same direction are obtained.

Journal Title: Acta Metallurgica Sinica (English Letters)

Year Published: 2018

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!