Photo from wikipedia

Microstructure, geometrical, and mechanical properties of copper wire in asymmetrical rolling process is experimentally investigated to determine the effects of microstructural properties on the process output parameters. The asymmetrical conditions… Click to show full abstract

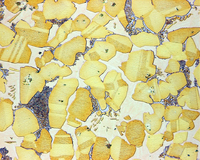

Microstructure, geometrical, and mechanical properties of copper wire in asymmetrical rolling process is experimentally investigated to determine the effects of microstructural properties on the process output parameters. The asymmetrical conditions applied in this work are introduced using different roll diameter ratios between the upper and the lower rolls. A number of experiments are carried out at room temperature with a laboratory rolling machine considering three different rolling reductions. The results reveal that as grain size in unrolled wire increase, the resulting radius at exit of the deformation zone as well as the total width of the rolled wire decrease. However, the width of the contact area increases. Furthermore, Vickers microhardness measurement is carried out in the section of the rolled wires at three different roll diameter ratios. The other findings indicate that by increasing roll diameter ratio, finer grain size and higher quantities of average hardness can be obtained.

Journal Title: Journal of the Brazilian Society of Mechanical Sciences and Engineering

Year Published: 2017

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!