Photo from wikipedia

The effect of various coating layers on the skin effect formation in thin-walled ductile iron casting with glass wool heat insulator has been investigated. Graphite, MgO, Zr, Zr + graphite, MgO + graphite coating… Click to show full abstract

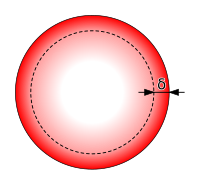

The effect of various coating layers on the skin effect formation in thin-walled ductile iron casting with glass wool heat insulator has been investigated. Graphite, MgO, Zr, Zr + graphite, MgO + graphite coating layers have been used. We observed that the different coating layers can be used to control cooling rate. Higher heat conductivity coating layer yields lower cooling rate, while lower heat conductivity yields higher cooling rate. The use of double layer can further increase cooling rate which was observed for Zr + graphite and MgO + graphite double coating layers. These may only be applicable in our system. Higher cooling rate system produces a casting product that has thinner skin effect. The use of MgO layer yields lower skin effect thickness which stood at 52.27 µm.

Journal Title: International Journal of Metalcasting

Year Published: 2017

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!