Photo from wikipedia

Calcium phosphate cements (CPCs) have been extensively investigated as scaffolds in bone tissue engineering in light of their chemical composition closely resembling the mineral component of bone extracellular matrix. Yet,… Click to show full abstract

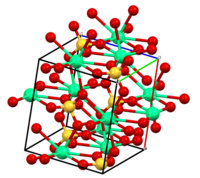

Calcium phosphate cements (CPCs) have been extensively investigated as scaffolds in bone tissue engineering in light of their chemical composition closely resembling the mineral component of bone extracellular matrix. Yet, the degradation kinetics of many CPCs is slow compared to de novo bone formation. In order to overcome this shortcoming, the use of porogens within CPCs has been suggested as a potential strategy to increase scaffold porosity and promote surface degradation. This study explored the usage of glucose microparticles (GMPs) as porogens for the introduction of macroporosity within CPCs, and characterized the handling properties and physicochemical characteristics of CPCs containing GMPs. Samples were fabricated with four different weight fractions of GMPs (10, 20, 30, and 40%) and two different size ranges (100-150μm and 150-300μm), and were assayed for porosity, pore size distribution, morphology, and compressive mechanical properties. Samples were further tested for their handling properties - specifically, setting time and cohesiveness. Additionally, these same analyses were conducted on samples exposed to a physiological solution in order to estimate the dissolution kinetics of GMPs and its effect on the properties of the composite. GMPs were efficiently encapsulated and homogeneously dispersed in the resulting composite. Although setting times increased for GMP/CPC formulations compared to control CPC material, increasing the Na2HPO4 concentration in the liquid phase decreased the initial setting time to clinically acceptable values (i.e. <15min). Incorporation of GMPs led to the formation of instant macroporosity upon cement setting, and encapsulated GMPs completely dissolved in three days, resulting in a further increase in scaffold porosity. However, the dissolution of GMPs decreased scaffold compressive strength. Overall, the introduction of GMPs into CPC resulted in macroporous scaffolds with good handling properties, as well as designer porosity and pore size distribution via selection of the appropriate size/weight fraction of GMPs. The data demonstrate that GMPs are promising porogens for the production of highly tunable porous CPC scaffolds. STATEMENT OF SIGNIFICANCE Calcium phosphate cements have shown great promise for the regeneration of bone. However, macropores (>100μm) are required for promoting bone ingrowth. Several studies have investigated methods to generate macroporosity within calcium phosphate cements but many of these methods either affect the cement setting or take weeks or months to generate the maximum porosity. This work offers a new method for generating macroporosity within calcium phosphate cements by utilizing glucose microparticles. The microparticles dissolve in less then 72h, thereby generating scaffolds with maximum porosity in short period of time. The results will offer a new method for generating macroporosity within calcium phosphate cements.

Journal Title: Acta biomaterialia

Year Published: 2017

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!