Photo from wikipedia

Abstract The process simulation tool Additive3D has been developed in Abaqus© 2017 to model the Extrusion Deposition Additive Manufacturing (EDAM) process for fiber-reinforced thermoplastic composites. This additive manufacturing (AM) method… Click to show full abstract

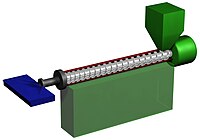

Abstract The process simulation tool Additive3D has been developed in Abaqus© 2017 to model the Extrusion Deposition Additive Manufacturing (EDAM) process for fiber-reinforced thermoplastic composites. This additive manufacturing (AM) method encompasses material deposition processes where geometries are constructed layer by layer and the resulting layer properties are highly anisotropic. The goal is to predict final deformed shapes and residual stresses of printed geometries due to the printing process and the material anisotropy. The resulting design tool allows to assess the outcomes of the printing process based on the part geometry, the printing material and the position control parameters. Material properties were characterized, and validation experiments, without additional calibration, show an excellent agreement between modeled and measured part deformation states with relative deviations below 7%. Due to the physics-based nature of the developed simulation tools, the simulations can be extended to account for different part scales, printing materials and printing histories.

Journal Title: Additive Manufacturing

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!