Photo from wikipedia

Abstract Using the segregation phenomenon of different materials in the mixing process, the dispersion nuclear fuel pellet with a core-shell structure was firstly designed and fabricated by an in-situ preparation… Click to show full abstract

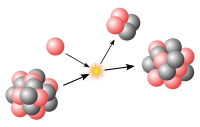

Abstract Using the segregation phenomenon of different materials in the mixing process, the dispersion nuclear fuel pellet with a core-shell structure was firstly designed and fabricated by an in-situ preparation process. This core-shell structure could prevent the metal matrix from reacting with water to generate hydrogen, which improves the safety property of the pellet. Furthermore, it provides a perspective on integrated manufacture of pellets and claddings by one-step preparation. Effects of mixing process parameters on the shell thickness were investigated in detail. The results indicate that: a three-quarter cycle sinusoid could be used to describe the change in shell thickness with rotational speed; and there is a negative linear relationship between shell thickness and volume percentage of ZrO 2 microspheres; the shell thickness increases as the particle size difference of ZrO 2 microspheres/glass beads increases. What’s more, an empirical formula describing the relationship between the shell thickness and these parameters has been established.

Journal Title: Annals of Nuclear Energy

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!