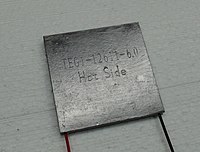

Photo from wikipedia

Abstract This paper presents a novel general single/multi-parameter optimization model for the thermoelectric cooler (TEC) based on the 1D resistance method, which precisely captures all the thermoelectrical effects and the… Click to show full abstract

Abstract This paper presents a novel general single/multi-parameter optimization model for the thermoelectric cooler (TEC) based on the 1D resistance method, which precisely captures all the thermoelectrical effects and the impacts of temperature-dependent thermoelectric properties, thermal operating conditions, and contact resistance at the solder layer, respectively. The explicit analytical expressions of designed optimal parameters, including the applied current, thermoelectric leg length, the cross-section area ratio of P/N-type thermoelectrical legs, and the number of leg pairs, are derived to maximize TEC performances (such as cooling capacity, coefficient of performance, or temperature difference between the cold/hot sides) under different operating conditions. The validation of the developed model is conducted through comparisons with the reported experimental data or 3D simulation results. The inherent correlations between the designed parameters are demonstrated and used to clarify the conflicting results in the literature. The ratio of leg length and its area cannot be assumed as an independent optimal parameter for large contact resistance. The filling ratio of thermoelectrical legs should be chosen as large as possible and limited by the manufacturing technology. It is demonstrated that the multiplication of applied current and number of leg pairs could be considered an independent optimal parameter, which provides a new strategy to design the available applied current for practical applications. The correlation between applied current and leg length is also discussed in detail. Multi-parameter optimization could remarkably improve the TEC performance compared with the single-parameter model, such as a significant improvement by 31% for the optimal cooling capacity. The cooling capacity is enhanced by 98% when the convective heat transfer coefficient of 1000 W/m2K at the cold/hot sides increases to 2000 W/m2K. A decrease of 15% for cooling capacity induced by the contact resistance is also observed. The present work provides a promising comprehensive tool for intensifying TEC performance maximization and clarifying its impact factors and the multi-parameter inherent correlation.

Journal Title: Applied Energy

Year Published: 2021

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!