Photo from wikipedia

Abstract In additive manufacturing based on the material extrusion of filled polymer melts, a correct description of the rheological behaviour of the processed material is an important requirement. In case… Click to show full abstract

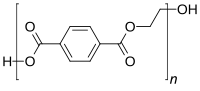

Abstract In additive manufacturing based on the material extrusion of filled polymer melts, a correct description of the rheological behaviour of the processed material is an important requirement. In case of highly filled feedstocks, complexities connected with a proper flow description are not only caused by the high packaging of powder particles (more than 50 vol.%) but also by the notable participation of polymer binder components in the quantification of shear viscosity. In this study, analytical expressions (master curves) of a true shear viscosity are developed to follow and continuously optimize the rheological dependence of the bulk feedstock on particular variables. A nickel-chromium-based compound (Inconel 718, content 59 vol.%) with thermoplastic binders of different molecular weight of polyethylene glycol was selected for the case study. The proposed master curves comprise simultaneously hitherto separately applied two corrections of an apparent shear viscosity: regarding the different capillary geometries with respect to entrance pressure and outlet extension, and determining an actual velocity profile based on shear rate distribution inside a feedstock. This approach eliminates the hitherto used non-Newtonian index, by means of which the logarithmic derivative was approximated. As the master curves depend exclusively on the shear rate and molecular weight of polyethylene glycol and do not involve any adjustable parameter, their application is straightforward. Their accuracy does not exceed experimental errors.

Journal Title: Applied Materials Today

Year Published: 2020

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!