Photo from wikipedia

Abstract More than 60 years of operation of water-cooled reactors have shown that local or general critical hydrogen concentration is one of the basic limiting criteria of zirconium-based fuel element… Click to show full abstract

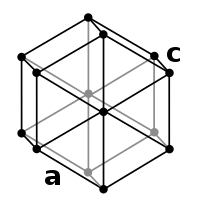

Abstract More than 60 years of operation of water-cooled reactors have shown that local or general critical hydrogen concentration is one of the basic limiting criteria of zirconium-based fuel element claddings. During the coolant radiolysis, released hydrogen penetrates and accumulates in zirconium alloys. Hydrogenation of zirconium alloys leads to degradation of their mechanical properties, hydride cracking and stress corrosion cracking. In this research the effect of titanium nitride (TiN) deposition on hydrogenation behavior of Ti-implanted Zr-1Nb alloy was described. Ti-implanted interlayer was fabricated by plasma immersion ion implantation (PIII) at the pulsed bias voltage of 1500 V to improve the adhesion of TiN and reduce hydrogen penetration into Zr-1Nb alloy. We conducted the comparative analysis on hydrogenation behavior of the Ti-implanted alloy with sputtered and evaporated TiN films by reactive dc magnetron sputtering (dcMS) and filtered cathodic vacuum arc deposition (FVAD), respectively. The crystalline structure and surface morphology were investigated using X-ray diffraction (XRD) and scanning electron microscopy (SEM). The elemental distribution was analyzed using glow-discharge optical emission spectroscopy (GD-OES). Hydrogenation was performed from gas atmosphere at 350 °C and 2 atm hydrogen pressure. The results revealed that TiN films as well as Ti implantation significantly reduce hydrogen absorption rate of Zr-1Nb alloy. The best performance to reduce the rate of hydrogen absorption is Ti-implanted layer with evaporated TiN film. Morphology of the films impacted hydrogen permeation through TiN films: the denser film the lower hydrogen permeation. The Ti-implanted interface plays an important role of hydrogen accumulation layer for trapping the penetrated hydrogen. No deterioration of adhesive properties of TiN films on Zr-1Nb alloy with Ti-implanted interface occurs under high-temperature hydrogen exposure. Thus, the fabrication of Ti-implanted layer with dense TiN films can be an effective way to protect Zr-1Nb alloy from hydrogen embrittlement.

Journal Title: Applied Surface Science

Year Published: 2018

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!