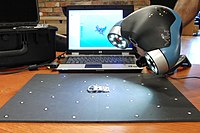

Photo from wikipedia

Abstract Inspection is vital in industrial plant construction and management. However, traditional inspection methods that rely on human involvement and paper documentation are becoming untenable as modern industrial plants are… Click to show full abstract

Abstract Inspection is vital in industrial plant construction and management. However, traditional inspection methods that rely on human involvement and paper documentation are becoming untenable as modern industrial plants are becoming larger and more complex than legacy facilities. Hence, an efficient and robust method is required to support the inspection of modern industrial plants. In this paper, an improved technique relying on terrestrial laser scanning (TLS) for data acquisition and normal-based region growing and efficient random sample consensus (RANSAC) for point cloud data processing is proposed for the on-site dimensional inspection of the piping systems of an industrial plant. Consequently, the as-built condition of the plant is assessed via a distance-based deviation analysis and a comparison of geometric parameters between the as-designed and as-built models. The method is validated using a dataset acquired from a compartment of a ship has verified the robustness and reliability of the proposed approach.

Journal Title: Automation in Construction

Year Published: 2018

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!