Photo from wikipedia

Because nanocellulose has a large specific surface area and abundant hydroxyl functional groups due to its unique nanomorphology, interest increases as an eco-friendly water treatment material. However, the distinctive properties… Click to show full abstract

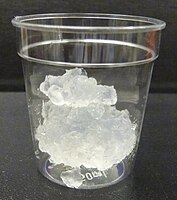

Because nanocellulose has a large specific surface area and abundant hydroxyl functional groups due to its unique nanomorphology, interest increases as an eco-friendly water treatment material. However, the distinctive properties of nanocellulose, which exists in a dispersion state, strongly hamper its usage in practical water treatment processes. Additionally, nanocellulose shows low performance in removing anionic pollutants because of its anionic characteristics. In an effort to address this challenge, regenerated cellulose (RC) hydrogel was fabricated through cellulose's dissolution and regeneration process using an eco-friendly aqueous solvent system. Subsequently, a crosslinking process was carried out to introduce the cationic functional groups to the RC surface PEI coating (P/RC). As a result, the PEI surface cationization process improved the mechanical rigidity of RC and showed an excellent Cr(VI) removal capacity of 578 mg/g. In addition, the prepared P/RC maintained more than 90% removal efficiency even after seven reuses.

Journal Title: Carbohydrate polymers

Year Published: 2022

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!