Photo from wikipedia

Abstract A novel biochar supported nanoscale iron sulfide (FeS) composite (CMC-FeS@biochar) combining the advantages of biochar, carboxymethyl cellulose (CMC), and FeS was synthesized and tested for Cr(VI) removal efficiency and… Click to show full abstract

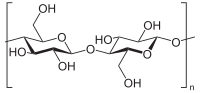

Abstract A novel biochar supported nanoscale iron sulfide (FeS) composite (CMC-FeS@biochar) combining the advantages of biochar, carboxymethyl cellulose (CMC), and FeS was synthesized and tested for Cr(VI) removal efficiency and mechanisms. FeS particles were effectively soldered onto the surface of biochar through OH, C C, O C O, C O, and Si O functional groups. The composite at a mass ratio of FeS:CMC: biochar = 1:1:1 displayed an enhanced Cr(VI) adsorption capacity of 130.5 mg/g at pH 5.5 compared to 38.6 mg/g for FeS and 25.4 mg/g for biochar. Surface sorption and reduction were the dominant removal mechanisms. At the equilibrium Cr(VI) concentration of 13.4 mg/L, 57% of Cr(VI) removal was attributed to reduction and 43% was ascribed to surface sorption. The adsorption kinetic data were adequately simulated with pseudo second-order kinetic model and mass transfer model, suggesting that sorption kinetics were the combination of chemisorption and external mass transfer. The Redlich-Peterson model fitted better than the Langmuir and Freundlich models in simulating the adsorption isotherm data, again suggesting a hybrid chemical reaction-sorption process. The Dubinin–Radushkevich isotherm model resulted in an adsorption energy of 10.0 kJ/mol, implying a chemisorption between Cr(VI) and CMC-FeS@biochar. The present study demonstrated the promise of CMC-FeS@biochar composite as a low-cost, “green”, and effective sorbent for removal of Cr(VI) in the environment.

Journal Title: Chemical Engineering Journal

Year Published: 2017

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!