Photo from wikipedia

Abstract To isolate injection and production zones from overlying formations and aquifers during geothermal operations, cement is placed in the annulus between well casing and the formation. However, wellbore cement… Click to show full abstract

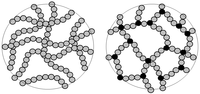

Abstract To isolate injection and production zones from overlying formations and aquifers during geothermal operations, cement is placed in the annulus between well casing and the formation. However, wellbore cement eventually undergoes fractures due to chemical and physical stress with the resulting time and cost intensive production shutdowns and repairs. To address this difficult problem, a polymer-cement (composite) with self-healing properties was recently developed by our group. Short-term thermal stability tests demonstrated the potential of this material for its application in geothermal environments. In this work, the authors unveil some of the physical and chemical properties of the cement composite in an attempt to better understand its performance as compared to standard cement in the absence of the polymer. Among the properties studied include material's elemental distribution, mineral composition, internal microstructure, and tensile elasticity. Polymer-cement composites have relatively larger, though not interconnected, levels of void spaces compared to conventional cement. Most of these void spaces are filled with polymer. The composites also seem to have higher levels of uncured cement grains as the polymer seems to act as a retarder in the curing process. The presence of homogeneously-distributed more flexible polymer in the cement brings about 60–70% higher tensile elasticity to the composite material, as confirmed experimentally and by density-functional calculations. The improved tensile elasticity suggests that the composite materials can outperform conventional cement under mechanical stress. In addition, calculations indicate that the bonding interactions between the cement and polymer remain stable over the range of strain studied. The results suggest that this novel polymer-cement formulation could represent an important alternative to conventional cement for application in high-temperature subsurface settings.

Journal Title: Cement and Concrete Composites

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!