Photo from wikipedia

Abstract Al2O3/Er3Al5O12 (EAG) binary eutectic ceramics were prepared by induction heating and the effects of the solidification process on the microstructure and properties of eutectic ceramic were investigated, such as… Click to show full abstract

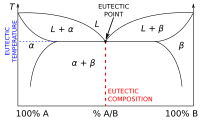

Abstract Al2O3/Er3Al5O12 (EAG) binary eutectic ceramics were prepared by induction heating and the effects of the solidification process on the microstructure and properties of eutectic ceramic were investigated, such as the Natural Cooling Solidified Method (NCS), the Bridgman Solidified Method (BSM), and the Zone Melting after NCS (ZMN), as well as the growth rate. The experimental results show that there are no pores and amorphous phases in the ZMN Al2O3/EAG solidified ceramic, which consists of EAG phase and Al2O3 phase. EAG phase is the matrix, where the Al2O3 phase is embedded, and these two phases form a "hieroglyphic" structure similar to that of BSM solidified ceramic. As the growth rate increased, the eutectic spacing decreased, and satisfied the relationship λ2v ≈ 60 (constant) for the both ZMN and BSM Al2O3/EAG solidified ceramics. And the hardness and fracture toughness gradually increased. For the same growth rate, the mechanical properties of the ZMN solidified ceramic are higher than those of the BSM one. The observation and analysis of the micro-cracks in the ZMN and BSM Al2O3/EAG solidified ceramics show that crack deflection and crack branching play key roles in improving the fracture toughness of directional solidification ceramics.

Journal Title: Ceramics International

Year Published: 2018

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!