Photo from wikipedia

Abstract In a properly made porous abrasive composite, the vitrified bond should ideally cover the grains and form a continuous network of bridges, and thus part of the heat energy… Click to show full abstract

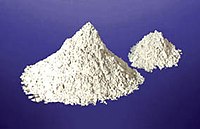

Abstract In a properly made porous abrasive composite, the vitrified bond should ideally cover the grains and form a continuous network of bridges, and thus part of the heat energy from the grinding process is also transferred to the vitrified bond. Until recently, most studies on the design of composite properties have focused mainly on improving their mechanical strength and wear resistance, but increasingly the very important aspect of their thermal properties is noticed. The vitrified Al2O3 composites were made from Al2O3 grains, vitrified bond of Na2O K2O Al2O B2O3 SiO2 and AlN nanopowder. The increase in porosity in the tested composites is the effect of the AlN decomposition reaction. Crystalline phases were identified in both composites - α-Al2O3 and NaAl11O17, but with a different percentage share in individual composites. In composites doped with AlN nanopowder, the proportion of NaAl11O17 crystalline phase decreases, due to its high susceptibility to reduction by Al, obtained from the AlN decomposition reaction. The product of the redox reaction is also Na+ ions, which may participate in the formation of the glass phase and thus increasing the fraction of the residual glass phase. As a result of the partial reduction of NaAl11O17 phase, an increase in α-Al2O3 content is observed. A higher proportion of α-Al2O3 phase with high thermal conductivity can be a factor that increases the rate of heat removal from the work zone.

Journal Title: Ceramics International

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!